RML Series Gear Head Metal Lathes: Engineering, Features, and Specifications #

Introduction #

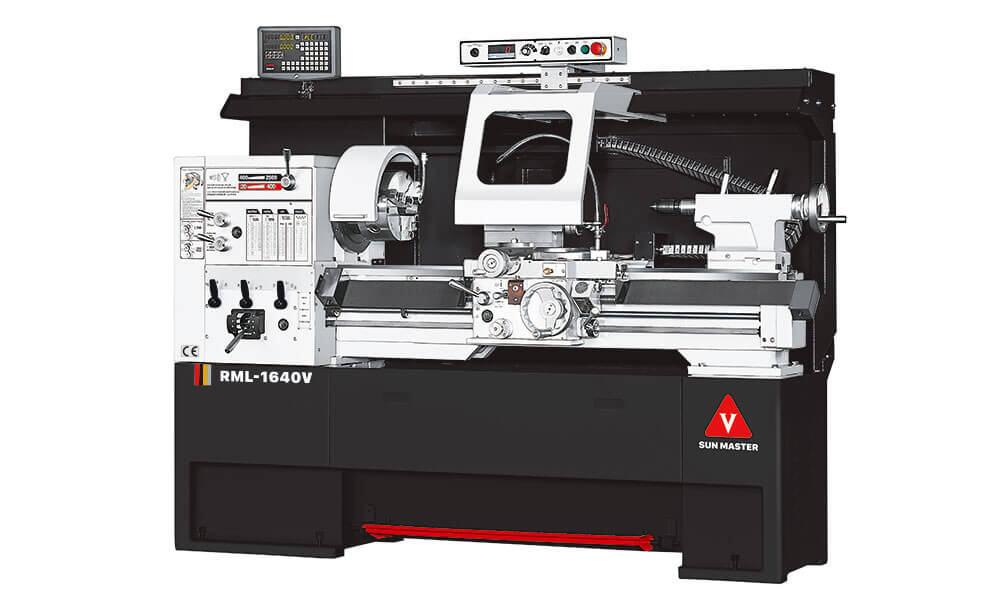

The RML Series Gear Head Metal Lathes are designed for precision, durability, and versatility in metalworking applications. This series includes models RML-1430, RML-1440, RML-1460, RML-1630, RML-1640, and RML-1660, each engineered to meet a range of operational needs.

Key Product Highlights #

- E.V.S models feature an automatic lubrication system for the headstock and an external tank for oil cooling.

- All models are constructed with a one-piece solid stand for enhanced stability.

- Universal feed gearbox and reversible apron are standard across the series.

- CE compliance is available upon request.

- Each model is equipped with a 52.5mm (2.066") spindle bore and ASA D1-6 spindle nose.

Technical Specifications #

| Model | RML-1430 | RML-1440 | RML-1460 | RML-1630 | RML-1640 | RML-1660 |

|---|---|---|---|---|---|---|

| Height of centers | 180mm (7.08") | 205mm (8.07") | ||||

| Swing over bed | Ø360mm (14.17") | Ø410mm (16.14") | ||||

| Swing in gap | - | Ø533mm (20.98") | - | Ø583mm (22.95") | ||

| Swing over cross slide | Ø212mm (8.35") | Ø262mm (10.3") | ||||

| Distance between centers | 800mm (31.5") | 1000mm (40") | 1500mm (60") | 800mm (31.5") | 1000mm (40") | 1500mm (60") |

| Width of bed | 260mm (10.236") | |||||

| Gap width in front faceplate | - | 135mm (5.31") | 225mm (8.85") | - | 135mm (5.31") | 225mm (8.85") |

| Spindle nose, internal taper | D1-6 / A1-6 (opt.), MT. No.6 | |||||

| Spindle center sleeve | MT. No.6 x MT. No.4 | |||||

| Spindle bore | Ø52.5mm (2.066") | |||||

| Spindle speed | 8 steps / 70~1800 RPM; OPT. 16 steps / 8P 40~1000 RPM, 4P 80~2000 RPM | |||||

| Carriage (Length on bed / Width) | 513mm (20.19") / 412mm (16.22") | |||||

| Cross slide travel | 220mm (8.6") | |||||

| Top slide travel | 125mm (4.92") | |||||

| Whitworth threads | 45 kinds / 2~72 T.P.I. | |||||

| Metric threads | 39 kinds / 0.2~14 mm | |||||

| D.P. threads | 21 kinds / 8~44 D.P. | |||||

| M.P. threads | 18 kinds / 0.3~3.5 M.P. | |||||

| Longitudinal feeds | 0.05~1.7 (0.002"~0.067") | |||||

| Cross feeds | 0.025~0.85 (0.001"~0.034") | |||||

| Quill diameter | Ø52mm (2.047") | |||||

| Quill travel | 152 mm (6") | |||||

| Taper of center | MT. No.4 | |||||

| Main spindle motor | 5HP4P OPT.5HP 4P / 2.5HP 8P; AC 3.7kW (5HP), Inverter | |||||

| Coolant pump | 1/8HP | |||||

| Weight (Net / Gross) | 1300kgs/1400kgs | 1350kgs/1470kgs | 1450kgs/1610kgs | 1350kgs/1450kgs | 1400kgs/1520kgs | 1500kgs/1660kgs |

| Packing sizes (L x W x H) | 2070mm (81.5") / 2270mm (89.4") / 2785mm (109.7") x 1120mm (44.1") x 1900mm (74.8") |

Specifications are subject to change without notice.

Standard Accessories #

- Backplate for 9" chuck

- Dead center MT.4

- Dead center MT.4 with carbide tip

- Spindle center sleeve MT.6

- Level pads (6 pcs)

- Tool set & box

- Operation manual & parts list

- Full length splash guard

- Halogen lamp

Optional Accessories #

Engineering Features #

- All castings are stabilized and stress relieved for long-term accuracy.

- Bed ways are hardened and ground to a minimum of HS-70.

- Turcite B coating is applied between the bed and carriage for smooth movement.

- The design ensures extremely low noise levels during operation.

- A foot brake pedal is included for safety.

- Built-in coolant pump and fittings are standard.

- CSS (constant surface speed control) is available for E.V.S. models upon request.

- The wider bed way design helps absorb vibration for improved machining results.

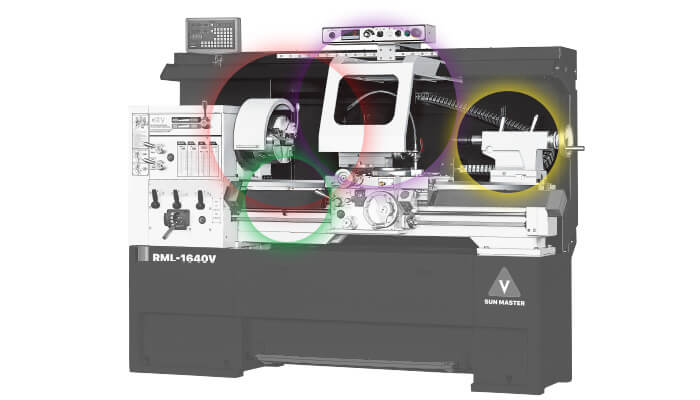

E.V.S. Model Electric Control #

- CE-compliant electric system available on request.

- The electric cabinet is sealed to protect against water, dirt, and contaminants.

- Main disconnect switch is provided for safety.

- Electric 1/4HP pump ensures headstock pressure lubrication, prolonging the life of gears and spindle.

- Combination of forced lubrication and oil bath system in the headstock.

Heavy Duty Spindle #

- Spindle is machined from forged alloy steel, hardened, ground, and dynamically balanced.

- Supported by high-grade precision taper roller and ball bearings at three points.

E.V.S. Headstock #

- Forced lubrication to all running points.

- Gears and shafts are hardened and ground for durability.

- RPM LED display indicator for easy monitoring and optimal constant surface speed.

- Electronic control panel is conveniently located on top of the headstock, featuring RPM display, speed control knob, emergency stop, and motor start button.

- Infinitely variable speed control with AC motor inverter.

- Two headstock gear speed ranges provide high torque in low range (20 to 400 RPM) and high range (400 to 2500 RPM).