Precision and Versatility in Conventional Gear Head Lathes #

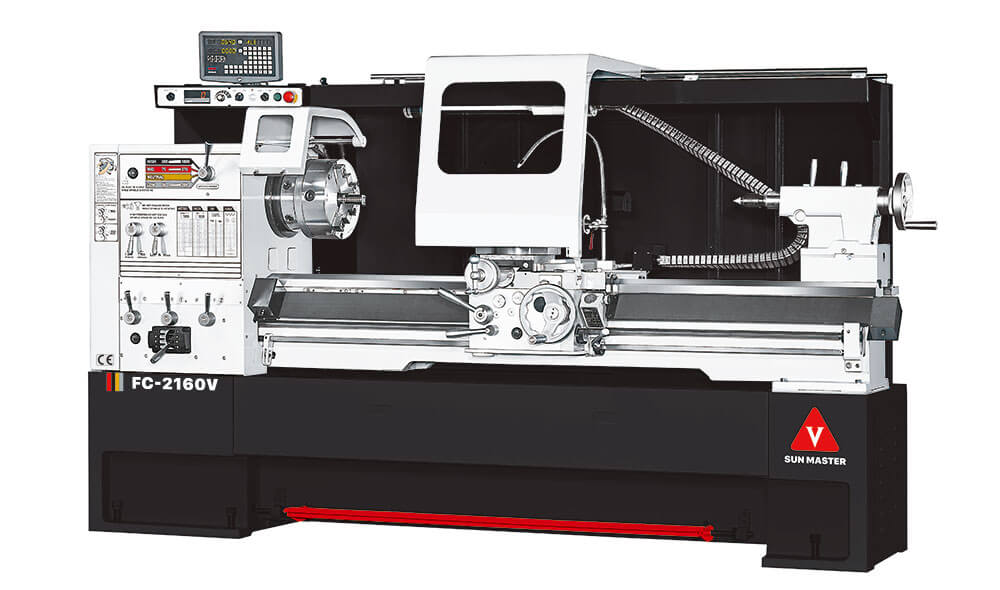

The FC Series Gear Head Conventional Lathe Machine by SUN MASTER® is engineered to address the evolving demands of modern machining. Built with a one-piece solid stand, this series ensures both stability and durability, making it a reliable choice for workshops seeking consistent performance.

Model Range #

- FC-1640

- FC-1660

- FC-1840

- FC-1860

- FC-1880

- FC-2140

- FC-2160

- FC-2180

Key Features #

- Universal Feed Gearbox & Reversible Apron: Each model is equipped with a universal feed gearbox and a reversible apron, enhancing versatility for a wide range of applications.

- Robust Spindle Bore: An 80mm (3.149") spindle bore with ASA D1-8 standard ensures compatibility with various tooling options.

- Hardened & Ground Cross Slide: The cross slide is treated for extended operational life, supporting reliable and precise machining.

- CE Compliance: All models can be supplied to meet CE standards upon request, ensuring safety and quality.

- Solid Construction: The bed ways are hardened and ground to a minimum of HRC48-55, and all castings are stabilized and stress relieved.

- Noise Reduction: The design incorporates features for extremely low noise levels during operation.

- Enhanced Usability: Includes a foot brake pedal, built-in coolant pump, and wider bed ways for vibration absorption.

- Smooth Operation: Y-Δ type spindle motor ensures smooth start and operation.

Technical Specifications #

| Model | FC-1640 | FC-1660 | FC-1840 | FC-1860 | FC-1880 | FC-2140 | FC-2160 | FC-2180 |

|---|---|---|---|---|---|---|---|---|

| Height of centers | 205 mm (8.07") | 231 mm (9.05") | 271 mm (10.67") | |||||

| Swing over bed | 410 mm (16.14") | Ø462 mm (18.11") | Ø542 mm (21.34") | |||||

| Swing in gap | 583 mm (22.95") | Ø650 mm (25.59") | Ø730 mm (28.74") | |||||

| Swing over cross slide | 262 mm (10.3") | Ø305 mm (12") | Ø387 mm (15.23") | |||||

| Distance between centers | 1000 mm (40") | 1500 mm (60") | 2200 mm (86.6") | |||||

| Width of bed | 320 mm (12.5") | |||||||

| Spindle nose, internal taper | D1-8 / A1-8 (opt.), Ø85mm Taper 1/19.18 | |||||||

| Spindle center sleeve | Ø85mm Taper 1/19.18 x MT. No.5 | |||||||

| Spindle bore | Ø80mm (3.149") | |||||||

| Spindle speed (12 steps) | 26, 40, 60, 90, 105, 145, 205, 305, 510, 715, 1000, 1500 rpm | |||||||

| Cross slide travel | 250 mm (9.84") | 300 mm (11.81") | ||||||

| Top slide travel | 150 mm (5.9") | |||||||

| Whitworth threads | 45 kinds / 2~72 T.P.I. | |||||||

| Metric threads | 39 kinds / 0.2~14 mm | |||||||

| D.P. threads | 21 kinds / 8~44 D.P. | |||||||

| M.P. threads | 18 kinds / 0.3~3.5 M.P. | |||||||

| Longitudinal feeds | 0.04~1.0 (0.0015"~0.04") | |||||||

| Cross feeds | 0.02~0.5 (0.00075"~0.02") | |||||||

| Quill diameter | Ø59 mm (2.322") | Ø68 mm (2.677") | ||||||

| Quill travel | 127 mm (5") | 153 mm (6") | ||||||

| Taper of center | MT. No.4 | |||||||

| Main spindle motor | std. 10 HP (7.5 kW), opt. 12.5 HP (9.375 kW) | |||||||

| Coolant pump | 1/8 HP | |||||||

| Net weight | 1750~2400 kg (varies by model) | |||||||

| Packing size (L x W x H) | 2400~3700 mm x 1155 mm x 1900 mm |

Specifications are subject to change without notice.

Standard Accessories #

- Backplate for 10" chuck

- Dead center MT.5

- Dead center MT.4 with carbide tip

- Spindle center sleeve (Ø85mm Taper 1/19.18)

- Level pads (6 pcs)

- Tool set & box

- Operation manual & parts list

- Full length splash guard

- Halogen lamp

Optional Accessories #

Construction and Design Highlights #

- All castings are stabilized and stress relieved for long-term durability.

- Bed ways are hardened and ground to a minimum of HRC48-55.

- Turcite B coating is applied between the bed and carriage for smooth movement.

- Low noise operation is achieved through thoughtful engineering.

- Foot brake pedal and built-in coolant pump are standard.

- Wider bed ways help absorb vibration, enhancing machining accuracy.

- Y-Δ type spindle motor ensures smooth starts and operation.

Component Details #

The FC Series Gear Head Conventional Lathe Machine is designed to deliver a balance of innovation, reliability, and performance, making it a strong addition to any machining environment.