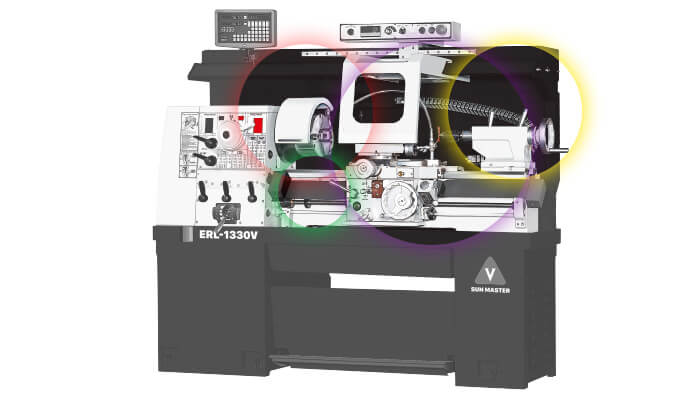

Overview of the ERL Series Gear-Head Lathe #

The ERL Series Gear-Head Lathe is engineered to deliver consistent performance and adaptability for a range of metalworking tasks. With robust construction, advanced features, and a focus on operator convenience, this series is suitable for both precision machining and general turning operations.

Key Product Highlights #

- Models Available: ERL-1330 / ERL-1340

- Headstock: All models feature an oil-bathed lubrication system for the headstock, ensuring smooth operation and longevity.

- Compliance: CE certification available upon request.

- Spindle Bore: 40mm (1.57") spindle bore, ASA D1-4.

Technical Specifications #

| Specification | ERL-1330 | ERL-1340 |

|---|---|---|

| Height of centers | 171mm (6.73") | 171mm (6.73") |

| Swing over bed | Ø342mm (13.46") | Ø342mm (13.46") |

| Swing in gap | - | Ø512mm (20") |

| Swing over cross slide | Ø205mm (8.07") | Ø205mm (8.07") |

| Distance between centers | 760mm (30") | 1000mm (40") |

| Width of bed | 230mm (9") | 230mm (9") |

| Gap width in front faceplate | 150mm (5") | 150mm (5") |

| Spindle nose, internal taper | D1-4, MT. No.5 | D1-4, MT. No.5 |

| Spindle center sleeve | MT. No.5 x MT. No.3 | MT. No.5 x MT. No.3 |

| Spindle bore | Ø40mm (1.57") | Ø40mm (1.57") |

| Spindle speed (gear steps) | 8 steps / 80~2000 RPM | 8 steps / 80~2000 RPM |

| Optional spindle speed | 16 steps / 4P 50~1350 RPM, 2P 100~2570 RPM | 16 steps / 4P 50~1350 RPM, 2P 100~2570 RPM |

| Carriage (L x W) | 400mm x 384mm | 400mm x 384mm |

| Cross slide travel | 180mm (7") | 180mm (7") |

| Top slide travel | 95mm (3.74") | 95mm (3.74") |

| Whitworth threads | 45 kinds / 2~72 T.P.I. | 45 kinds / 2~72 T.P.I. |

| Metric threads | 39 kinds / 0.2~14 mm | 39 kinds / 0.2~14 mm |

| D.P. threads | 21 kinds / 8~44 D.P. | 21 kinds / 8~44 D.P. |

| M.P. threads | 18 kinds / 0.3~3.5 M.P. | 18 kinds / 0.3~3.5 M.P. |

| Longitudinal feeds | 0.05~1.7 (0.002"~0.067") | 0.05~1.7 (0.002"~0.067") |

| Cross feeds | 0.025~0.85 (0.001"~0.034") | 0.025~0.85 (0.001"~0.034") |

| Quill diameter | Ø50mm (1.968") | Ø50mm (1.968") |

| Quill travel | 112mm (4.5") | 112mm (4.5") |

| Taper of center | MT. No.3 | MT. No.3 |

| Main spindle motor | OPT. 5HP 2P/2.5HP 4P | OPT. 5HP 2P/2.5HP 4P |

| Coolant pump | 1/8 HP | 1/8 HP |

| Weight (Net/Gross) | 850/950kgs | 1000/1120kgs |

| Packing size (L x W x H) | 2000mm x 965mm x 1900mm | 2270mm x 965mm x 1900mm |

Specifications are subject to change without notice.

Standard Accessories #

- Backplate for 7" chuck

- Dead center MT.3

- Dead center MT.3 with carbide tip

- Spindle center sleeve MT.5

- Level pads (6 pcs)

- Tool set & box

- Operation manual & parts list

- Full length splash guard

- Halogen lamp

Optional Accessories #

Construction and Design Features #

- All castings are stabilized and stress relieved for durability.

- Bed ways are hardened and ground to a minimum of HS-70 for wear resistance.

- Operates with extremely low noise levels.

- Equipped with a foot brake pedal for safety.

- Built-in coolant pump and fittings included.

- CSS (constant surface speed control) available on request for E.V.S. models.

- Wider bed way design enhances vibration absorption.

Component Highlights #

Headstock #

- Vibration-absorbent and deflection-free housing.

- Gears are hardened and ground using MAAG or REISHAUER processes.

Gear Box #

- Universal design supports a wide range of inch, metric, M.P., and D.P. threads without the need for change gears.

Apron #

- Right-hand or left-hand wheel available upon request.

- Integrated automatic control for longitudinal and cross feeds, including forward and reverse.

Carriage & Slide #

- Anti-float design with backlash eliminator fitted in the cross slide nut.

- Safety clutch on the feed shaft.

- One-shot lubrication for carriage and top slide.

- Dual dials for inch system screws; metric dial for metric system.

Heavy Duty Spindle #

- Machined from forged alloy steel, hardened, ground, and dynamically balanced.

- Supported by high-grade precision taper roller and ball bearings at three points.

For further details or inquiries, please visit the Sun Master ERL Series Gear-Head Lathe page.