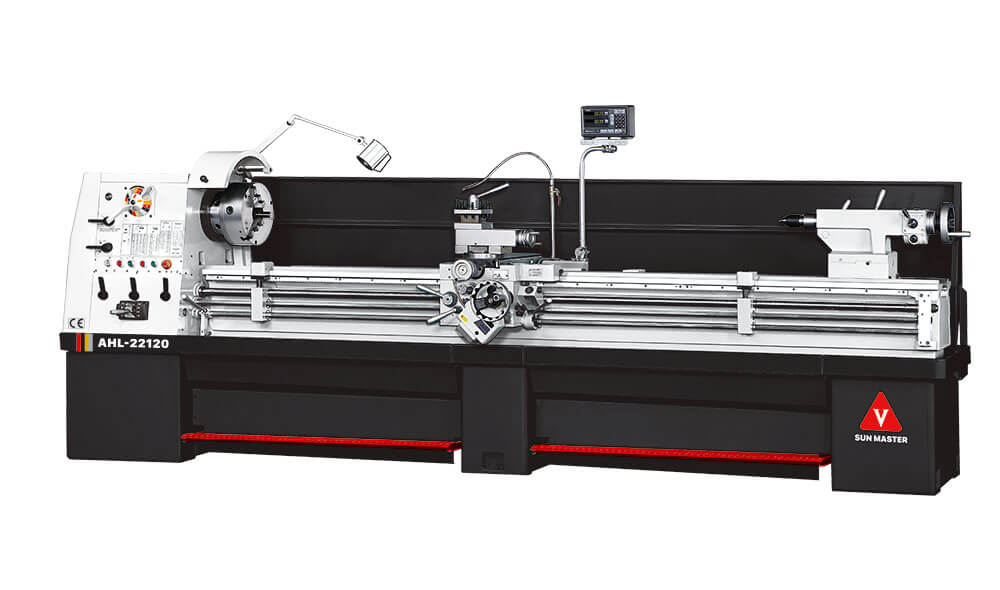

Advanced Manual Lathes for Demanding Machining Environments #

Overview #

The AHL Series Clutch Type Lathe is engineered to deliver reliable performance and precision for a variety of turning applications. This series includes multiple models—AHL-1840, 1860, 1880, 18120, 2240, 2260, 2280, and 22120—each equipped with a mechanical clutch (excluding E.V.S. models), an automatic lubrication system for the headstock, and an external oil cooling tank. All models are designed to meet CE standards upon request and feature an 80mm (3.149") spindle bore with ASA D1-8 spindle nose.

Key Specifications #

- Height of Centers: 230mm (9.055") for 18" models, 280mm (11.02") for 22" models

- Swing Over Bed: Ø460mm (18.11") for 18" models, Ø560mm (22.04") for 22" models

- Swing in Gap: Ø710mm (27.95") for 18" models, Ø808mm (31.81") for 22" models

- Swing Over Cross Slide: Ø298mm (11.93") for 18" models, Ø390mm (15.35") for 22" models

- Distance Between Centers: 1000mm (40"), 1500mm (60"), 2000mm (80"), 3000mm (120")

- Bed Width: 345mm (13.58")

- Gap Width in Front of Faceplate: 250mm (9.84")

- Spindle Bore: Ø80mm (3.149")

- Spindle Speed: 16 steps, 20–1600 RPM

- Disc Clutch: For forward and reverse operation

- Carriage Dimensions: 543mm (21.37") length on bed, 542mm (21.33") width

- Cross Slide Travel: 272mm (10.7")

- Top Slide Travel: 135mm (5.31")

- Threading Capabilities:

- Whitworth: 38 kinds, 2–72 TPI

- Metric: 40 kinds, 0.4–14 mm

- D.P.: 21 kinds, 8–44 D.P.

- M.P.: 18 kinds, 0.3–3.5 M.P.

- Feeds:

- Longitudinal: 0.04–1.0 mm (0.0015"–0.04")

- Cross: 0.02–0.5 mm (0.00075"–0.02")

- Tailstock:

- Quill Diameter: Ø76mm (3")

- Quill Travel: 165mm (6.5")

- Taper: MT. No.5

- Main Spindle Motor: 10HP or 12.5HP (model dependent)

- Coolant Pump: 1/8 HP

- Weight: Ranges from 2000kg to 3150kg (net), depending on model and length

- Packing Size: Length from 2535mm (99.8") to 4624mm (182"), width 1120mm (44.1"), height 1900mm (74.8")

Specifications are subject to change without notice.

Standard Accessories #

- Backplate for 12" chuck

- Dead center MT.5 (standard and carbide tip)

- Spindle center sleeve MT.7

- Level pads (8 pcs)

- Tool set and box

- Operation manual and parts list

- Halogen lamp

- Full-length splash guard

Optional Accessories #

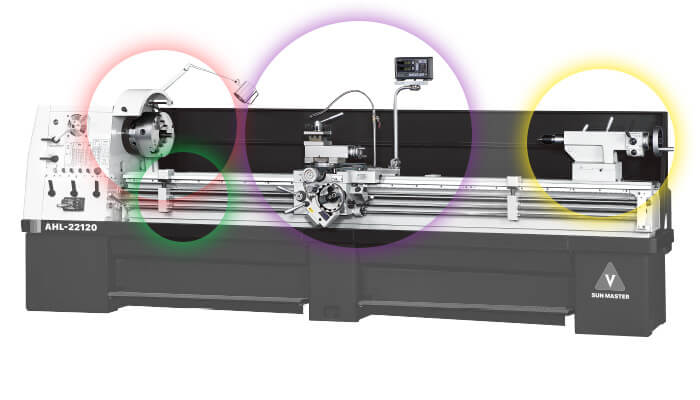

Construction and Performance Features #

- All castings are stabilized and stress relieved for durability.

- Bed ways are hardened and ground to a minimum of HS-70.

- Turcite B coating is applied between the bed and carriage for smooth movement.

- Low noise operation is achieved through careful engineering.

- Foot brake pedal is included for safety.

- Built-in coolant pump and fittings are standard.

- CSS (constant surface speed control) is available for E.V.S. models upon request.

- The wide bed design enhances vibration absorption.

Lubrication System #

- Oil sight window allows for easy monitoring of oil levels.

- Pressure lubrication in the headstock ensures proper lubrication and cooling during high-speed cutting.

- Splash lubrication is used in the feed gearbox and apron.

Additional Highlights #

- The headstock housing is designed to absorb vibration and resist deflection.

- Gears are hardened and precision ground using MAAG or REISHAUER technology.

- The universal gearbox supports a wide range of inch, metric, M.P., and D.P. threads without the need for change gears.

- The apron offers integrated automatic control for longitudinal and cross feeds, as well as forward and reverse feeds. R/H or L/H wheel configuration is available upon request.

- Carriage and slide feature an anti-float backlash eliminator, safety clutch at the feed shaft, and one-shot lubrication for carriage and top slide. Dual dials are provided for inch and metric systems.

- Safety is enhanced with nylon safety gears in the end train and a shear pin in the leadscrew.

- The spindle is machined from forged alloy steel, hardened, ground, and dynamically balanced, supported by high-grade precision taper roller and ball bearings.

For more information or to inquire about specific models, please visit the AHL Series Clutch Type Lathe page.