Manual Lathe Machines: Structure, Applications, and Key Advantages #

A conventional lathe machine, often referred to as an engine lathe or manual lathe, is a fundamental tool in metalworking. It is designed for a variety of machining operations, making it a versatile and widely adopted solution for shaping, cutting, drilling, and turning cylindrical workpieces.

Structure and Functionality #

Conventional lathes are typically composed of a horizontal bed, a headstock at one end, and a tailstock at the other. The workpiece is securely clamped between the headstock and tailstock, allowing it to rotate along its axis. A cutting tool, mounted in a tool post, is then brought into contact with the rotating workpiece to remove material and achieve the desired shape.

These machines are capable of handling a range of operations, including:

- Facing

- Turning

- Drilling

- Boring

- Threading

- Taper turning

Such versatility makes them suitable for manufacturing components like shafts, bushings, pulleys, and other cylindrical parts. Their precision and adaptability allow them to be used in both small-scale workshops and large industrial environments.

Product Range #

With a highly skilled R&D team, SHUN CHUAN® offers an extensive selection of high-speed precision manual metal lathes. The product lineup includes:

The range covers machines from small sizes (13" swing over bed and 30" distance between centers) to medium sizes (30" swing over bed and 200" distance between centers). These manual toolroom lathes are suitable for educational purposes, toolrooms, and general production lines, meeting a wide variety of job requirements.

Advantages of SHUN CHUAN® Conventional Lathes #

-

Cost-effectiveness: Conventional lathe machines are generally more affordable than CNC lathes due to their simpler design and lack of complex electronic controls. This makes them a practical choice for small-scale workshops or businesses with budget constraints.

-

Versatility: Manual toolroom lathes are highly versatile, capable of performing a wide range of machining operations such as turning, facing, drilling, boring, threading, and tapering. With skilled operation and appropriate tooling, they can produce complex shapes and profiles, making them suitable for both small-batch production and custom machining.

-

Flexibility and Adjustability: Operators have direct control over the cutting tool and machining process. Speed, feed rate, depth of cut, and tool position can be easily adjusted to meet specific workpiece requirements. This flexibility allows for on-the-fly modifications, making these machines adaptable to various materials and machining needs.

-

Skill Development: Operating a conventional lathe requires a certain level of skill and craftsmanship. Machinists gain hands-on experience in setup, alignment, and operation, developing a deep understanding of machining processes, tooling, and work-holding techniques. These skills are valuable for a range of applications and provide a strong foundation for transitioning to CNC machines.

-

Maintenance and Repair: With simpler mechanical systems compared to CNC lathes, conventional lathes are generally easier to maintain and repair. Components are more accessible, and repairs or replacements can often be performed without specialized knowledge or expensive parts, resulting in reduced downtime and lower maintenance costs.

-

Education and Training: Conventional lathes are widely used in educational institutions and vocational training centers to teach machining principles and techniques. Learning on manual machines helps students understand the fundamentals of machining, including tool selection, feeds and speeds, and manual control, before advancing to CNC technology.

While CNC lathes offer automation, precision, and productivity, SHUN CHUAN® conventional lathes continue to provide significant value in terms of cost-effectiveness, versatility, flexibility, skill development, maintenance, and training. The choice between conventional and CNC lathes depends on specific requirements, production volumes, budget, and the desired level of automation.

For further information or assistance regarding manual toolroom lathe machines, please contact us.

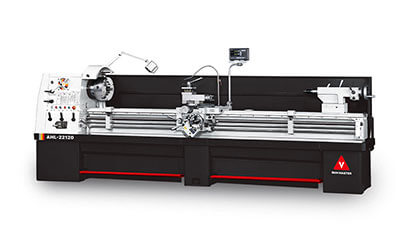

All Gear-Head Lathe

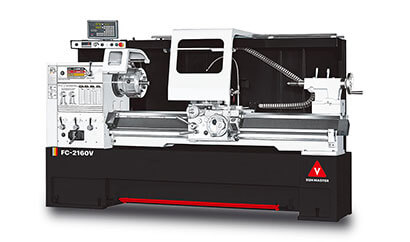

All Gear-Head Lathe Variable Speed Lathe

Variable Speed Lathe Clutch Type Lathe

Clutch Type Lathe